Robotmaster®

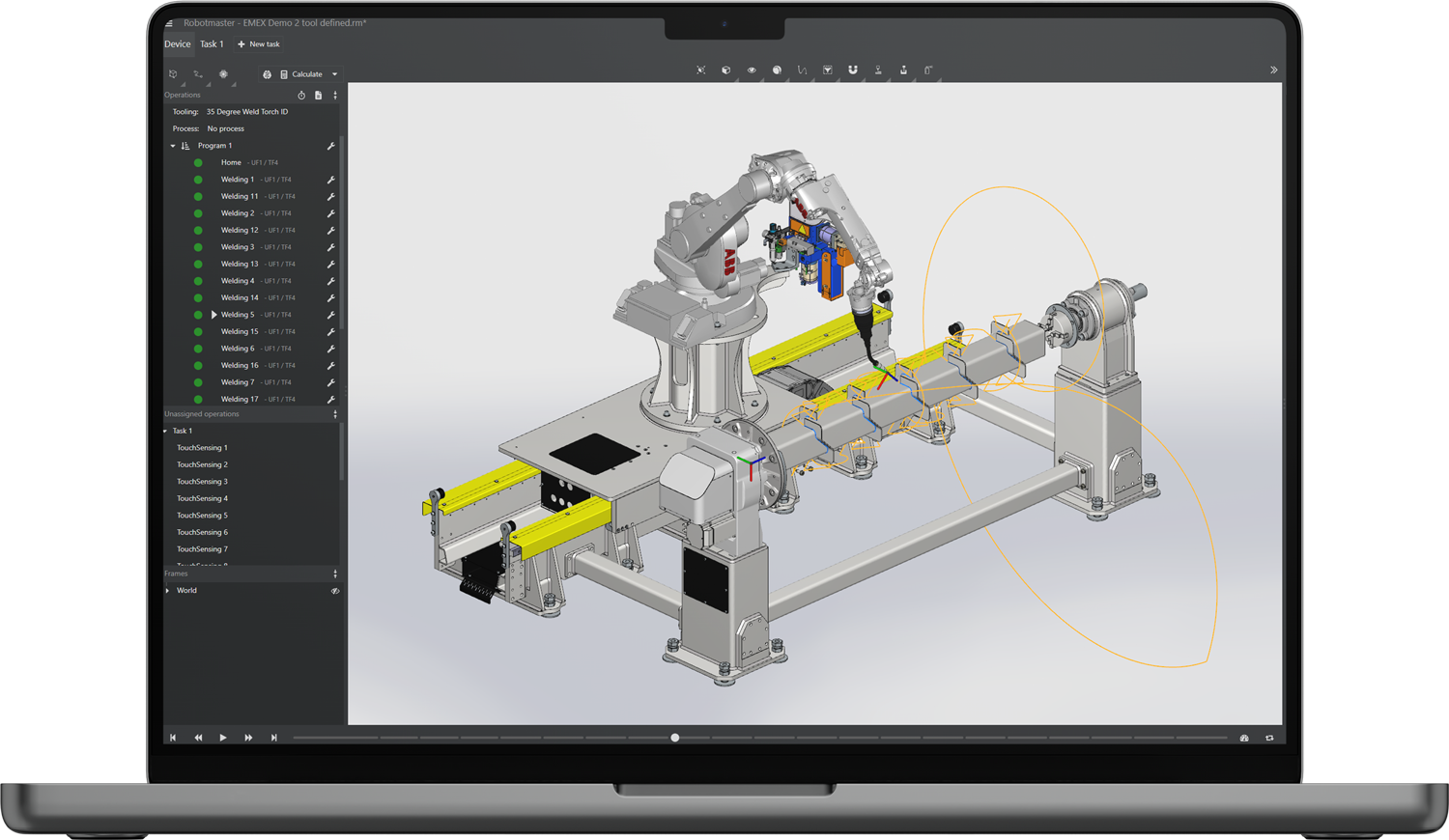

RobotMaster® delivers unmatched, full-function offline programming capability for robots.

It allows for easy programming of precise robot motion control and quick generation of path trajectories of any size, with minimal programmer intervention.

Key advantages of RobotMaster®

Consistently Higher-Quality Welds

If ultimate quality’s the goal, then the solution has to be a Plazmax robotic welding cell. Even the most experienced professional welder can’t compete with the quality and consistency of the weld produced by a well setup robotic rig.

Unleash Productivity

Robotic automation allows the typical 8-hour workplace to be retooled for 12, 18 or even 24-hour service. Not only is the uplift in productivity huge, staff who’d normally be absorbed by manual and repetitive work can be reassigned to other productive tasks.

Minimise Waste and Rework

Regardless of the scale of your operation, overwelding can be a huge source of waste. Plazmax’s proprietary Robotmaster software uses ultra-precise specifications to minimise metal filler costs without compromising bond strength.

Reduced Post-Weld Cleanup

Even with a robotic rig some post-weld cleanup is unavoidable, but with less wasted material and spattering, cleanup time and downtime between projects is minimised.

Unleash Faster, More Efficient Road to the Market

The granular control available with Robotmaster software lets users adapt quickly to new tasks and programme them to be infinitely repeatable. That kind of agility is a huge benefit to operations of all scales looking for a competitive advantage.

Safety

Robot cells distance operators from hazardous operating conditions and repetitive tasks that can have negative long-term effects. By removing human fatigue from the equation, error and injury are also no longer problematic.

Finance Options

Although it’s obvious to most the Return On Investment a high-tech piece of equipment can provide, banks and lenders don’t always understand your industry and the importance of such purchases.